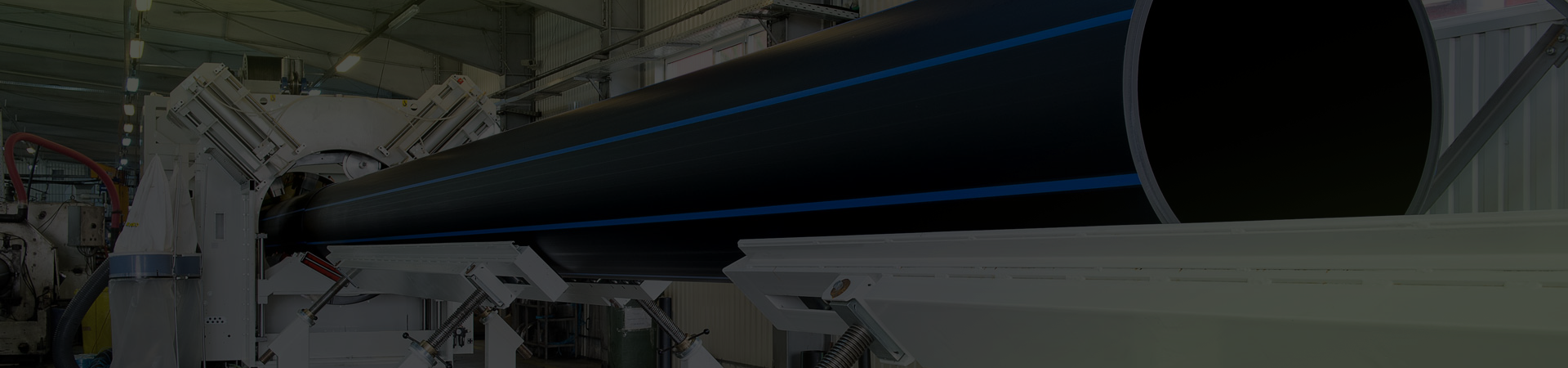

Screw & Barrel

Our precision-engineered Screw & Barrel assemblies are designed to deliver exceptional performance, durability, and efficiency in a wide range of plastic processing applications, including extrusion, injection molding, and blow molding.

Manufactured using high-grade alloy steel and advanced heat-treatment techniques, these components ensure:

- Excellent wear resistance

- Corrosion protection

- High output and melt quality

- Optimized plasticizing performance

Process & Specifications

- Twin Screw & Twin Barrel made from EN-41B steel (MUSCO - Mahindra Eugene make)

- Material conditioned by thermal process.

- Screw Profiling and flight Cutting made on fully Imported CNC thread milling machine.

- Honing surface in side the Barrel quality to achieve superior internal bore finish.

- Twin Screw polished by special purpose polishing machine.

- Devloped material stressess under process removed through stabilizaing after stabilized the material.

- Twin Screw & Twin Barrel are nitride hardened, with hardness maintained at up to 70 HRC.

- Nitride layer thickness maintained up to 0.4 to 0.5mm.

- Twin barrel in side of barrel fitted HSS sleeve.

- Tungsten Carbide coating on compression and venting zones of Twin Screw.

- Twin Screw Should be straight within 0.1 mm tolerance

- Close loop water circulating coolant filling in side of both Twin Screw.

- Twin Screw outer diameter Grinding, polishing ,buffing done.

- Permissible tolerances maintained for twin screw and twin barrel as per design.